Application:

For, Granuals like, HDPE / PP/ LDPE / LLDPE/ HM / Master Batch / Calcium / Talk / Filler etc.

Scope Of Supply:

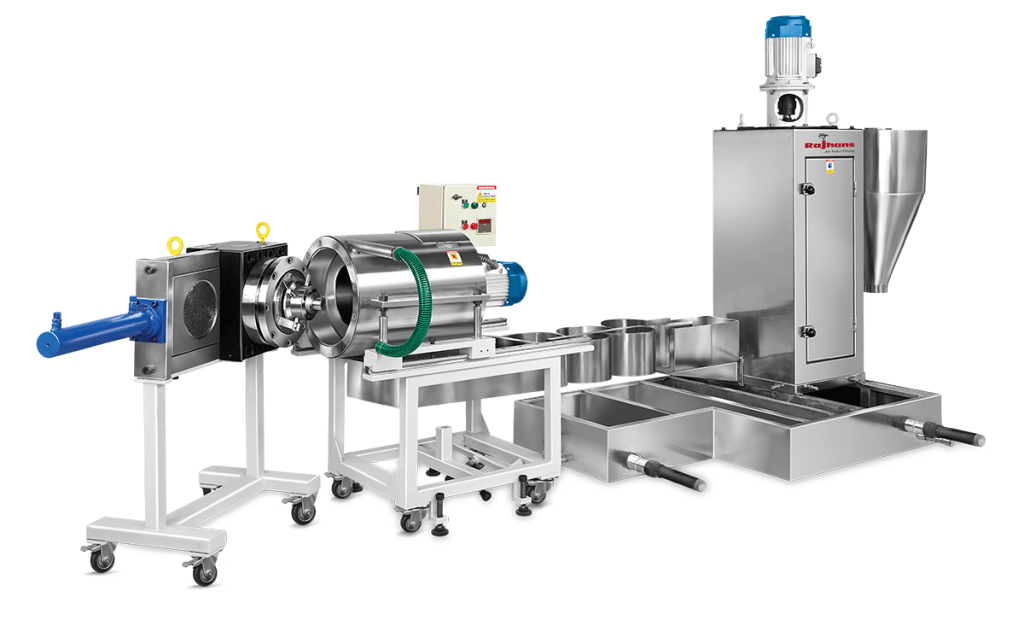

- Complete Die Face Cuter unit with Motor on Sliding Plateform.

- Die as per customize (Depends on Screw, Output, Material, Pressure Etc)

- Complete water tank / fabricated ways to separator.

- Separator with rotor & Motor.

- Cyclone attached to separator.

- Bottom water tank with partition, inlet and outlet.

- Electrical Panel with A.C. drive for variable speed of cutter.

Advantages:

- Heavy Wastage Control

- Production Increases

- Consistence size of Polymers

- Easy maintenance

- Fast color changes

- Improved good dryness of Granules

- Variable granules size available

- Melt flow pressure uniformly

- Easy to run in operation

- Very low power consumption

- All parts made from S.S.304 for longer life

General Information:

- Face cutting type: WATER CUTTER TYPE

- Frame structure

- Separator

- Bottom tank size:1600 x 1000 x 220 MM

- Water Pump: Standard Motor

- Pump Motor

- General Piping: as per required.

- Separator Motor

- Adopter & size cutting holder

- Knife hardening: 60 to 62 HRC.

- Qty of Knife: 04 Nos.

- Cutter Motor Capacity: 2 H.P. with (A.C. Drive) Variable RPM

- Cooling Cyclone

- Rotor of Separator RPM: 1440 RPM

- Water Tank

- Electric Panel – Box type with A.C. Drive for Die Face Cutter

- Total Weight: 750 Kgs.

- Overall Size: 15’L X 7’B X 7’H ft.