Keeping in with the spirit of finding new and innovative solutions in the field of plastics extrusion, Rajhans has now developed Breaker Plates Cleaner and Mesh/Filter Cleaning Furnace/Oven for plastic industries. These systems are very compact cleaning ovens with accurately controlled process for cleaning of variable filters/tools.

Applications:

To clean – Meshes, Breaker Plates, Breaker Plungers, Mould Parts, Extruder Parts, Die Parts, Nozzles.

To be cleaned without deformation.

Advantages:

- Safe, reliable and precise thermal cleaning process with no risk of damage to sensitive parts

- Low cost self-acting temperature so no risk to operators

- Easy to operate heavy-duty door with wheels for opening and closing

- Short cleaning cycle – 10-20-30 minutes

- Inside temperature controllable from 0ºC to 500ºC

- Easy to load and easy to unload

- Smoke/gas having temperature of 50º to 60º is blown out from the top pipe

- Heaters and blowers are connected to each other in electrical panel so that it leads to smoother operation and power saving

- Prevention (or reduction) of production line wastage due to mesh

- Saves manpower as well as the fatigue related to it

- Improvement in the quality of output

- Decrease in the cost of meshes.

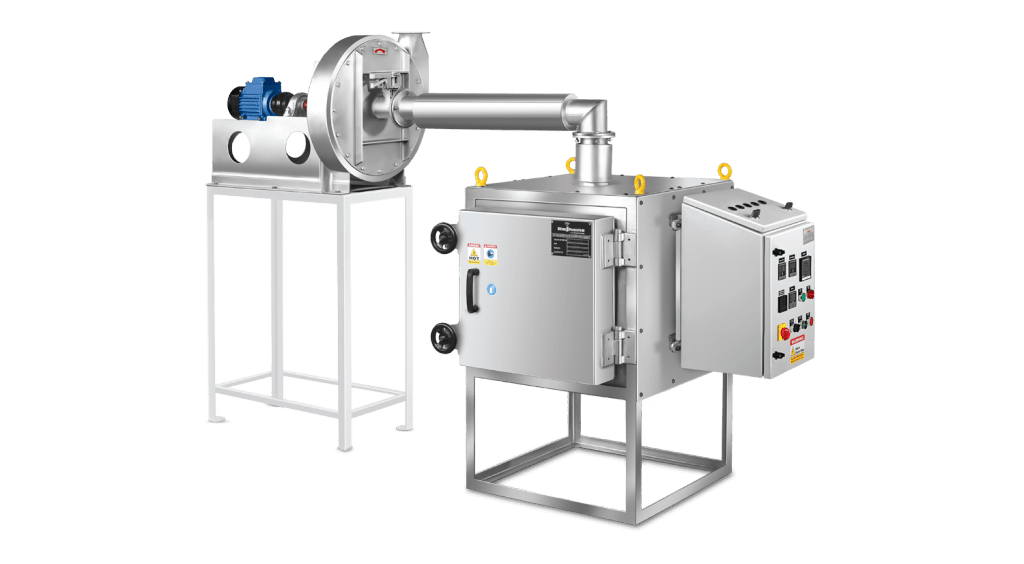

Scope of supply:

- Electric furnace with stand

- Electric tubular heaters

- Electric panel for temperature control

- Temperature controller

- ‘J ” type temperature sensor

- Fork and shocks for handling

- Centrifugal blower (0.5)

- Bearing housing

- Blower stand with Motor

- Smoke/gas exhaust pipe with insulation cover

Features:

- Parts can be cleaned in short time

- Proper cleaning as per your requirement

- Temperature controller to control the cycle time automatically

- Precision spares/parts are not damaged in this operation.